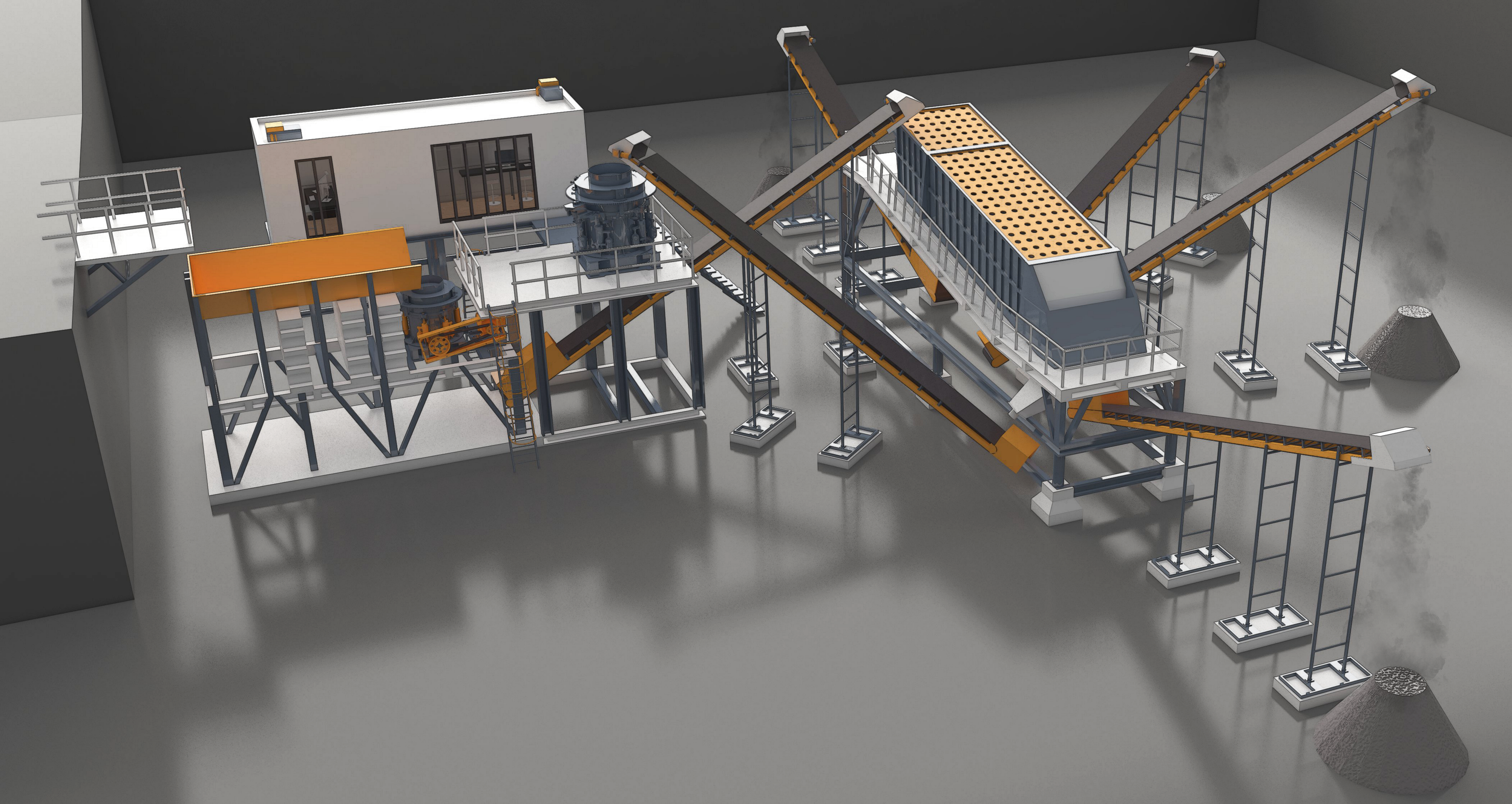

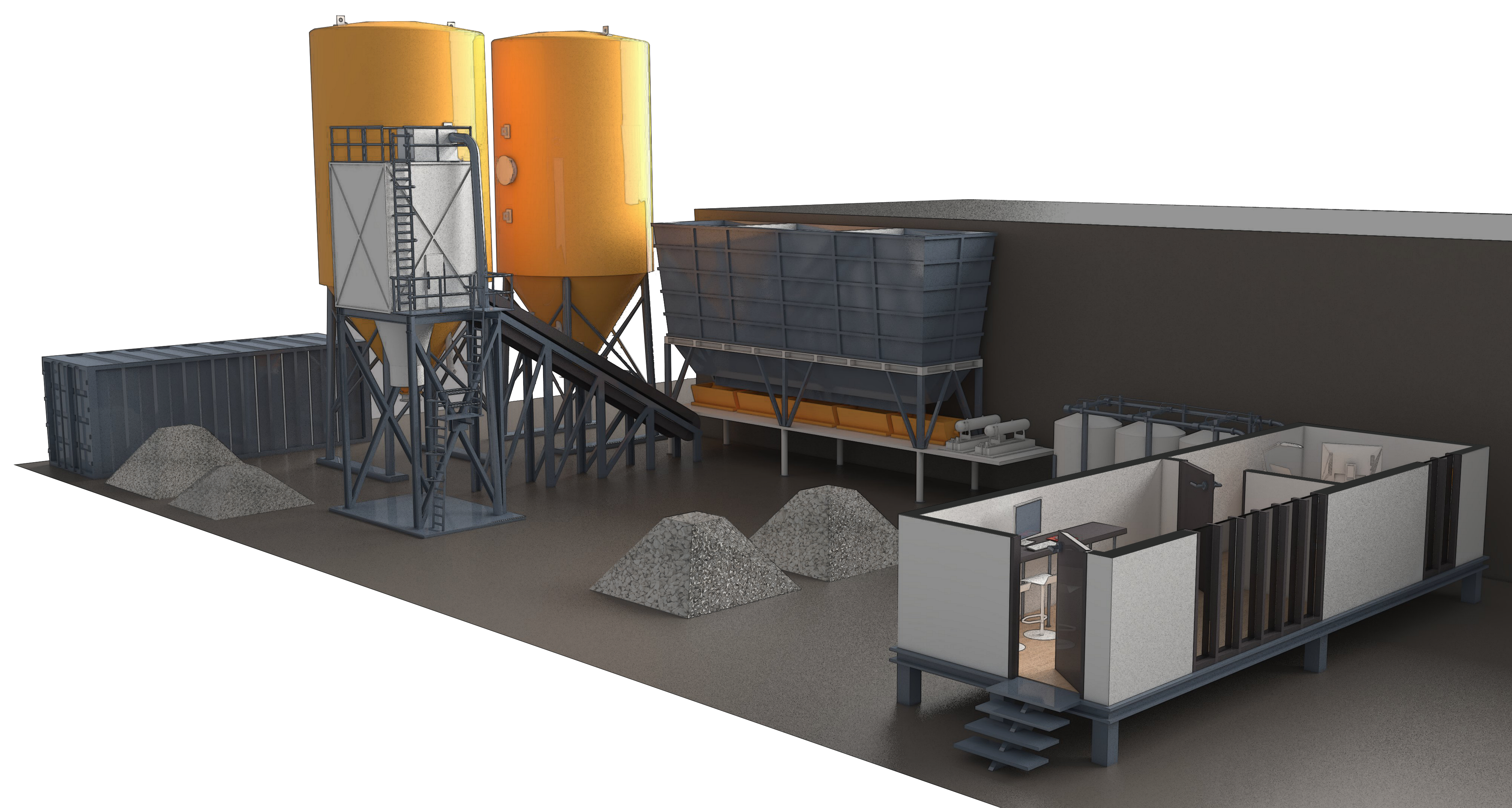

Aggregate industry

KontrolON guides you towards streamlining your production flow, costs and power consumption. The system enables you to monitor electricity consumption of the entire production plant (main belt, exit belts, grinding mill, washing tub, trommel screen) of a particular phase (crushing, screening, etc.) and a specific processing of each material.

In addition, thanks to a customised reporting service, KontrolON generates summaries regarding production, energy consumed, overall KPI, capacity rate, hours worked and power-on hours, average capacity and the percentage of deviation in comparison to the established benchmark.

Production data

Production details:

- Overall production details: tons and cubic metres

- Average capacity: tons/hour and metres/hour

- Factory operational details: power-on hours and idle time

- Instant capacity: tons/hour

Alerts

Generation and transmitting of customised alerts via push notifications appearing on your PC, tablet, smartphone and app.

- Factory operational status alerts: real and potential capacity

Alerts are activated when a certain parameter (minimum, maximum, average, summary) is either above or below the established threshold.

Costs and emissions

Breakdown of the incurred costs for the factory power supply:

- Overall costs

- Costs per ton (€/t)

- Average CO2 emissions per kWh produced and their weighted impact in the overall environmental impact of the factory

Indices and consumption

Overall power consumption monitoring and breakdown by specific process (crushing, washing, screening, etc.):

- Consumption analysis: influence of each production phase on a ton of material produced

- Process KPIs: crushing kWh/t, washing kWh/t, screening kWh/t

- Overall KPI: KwH/t