Bitumen industry

Thanks to KontrolON, companies operating in this industry that produce and process bituminous conglomerate are able to meet various requirements of their customers. The efficiency of this tool facilitates and simplifies production and energy consumption control, giving detailed information on production sites and advising on potential malfunctioning (e.g., deactivation of the bitumen heating system at night).

Production data

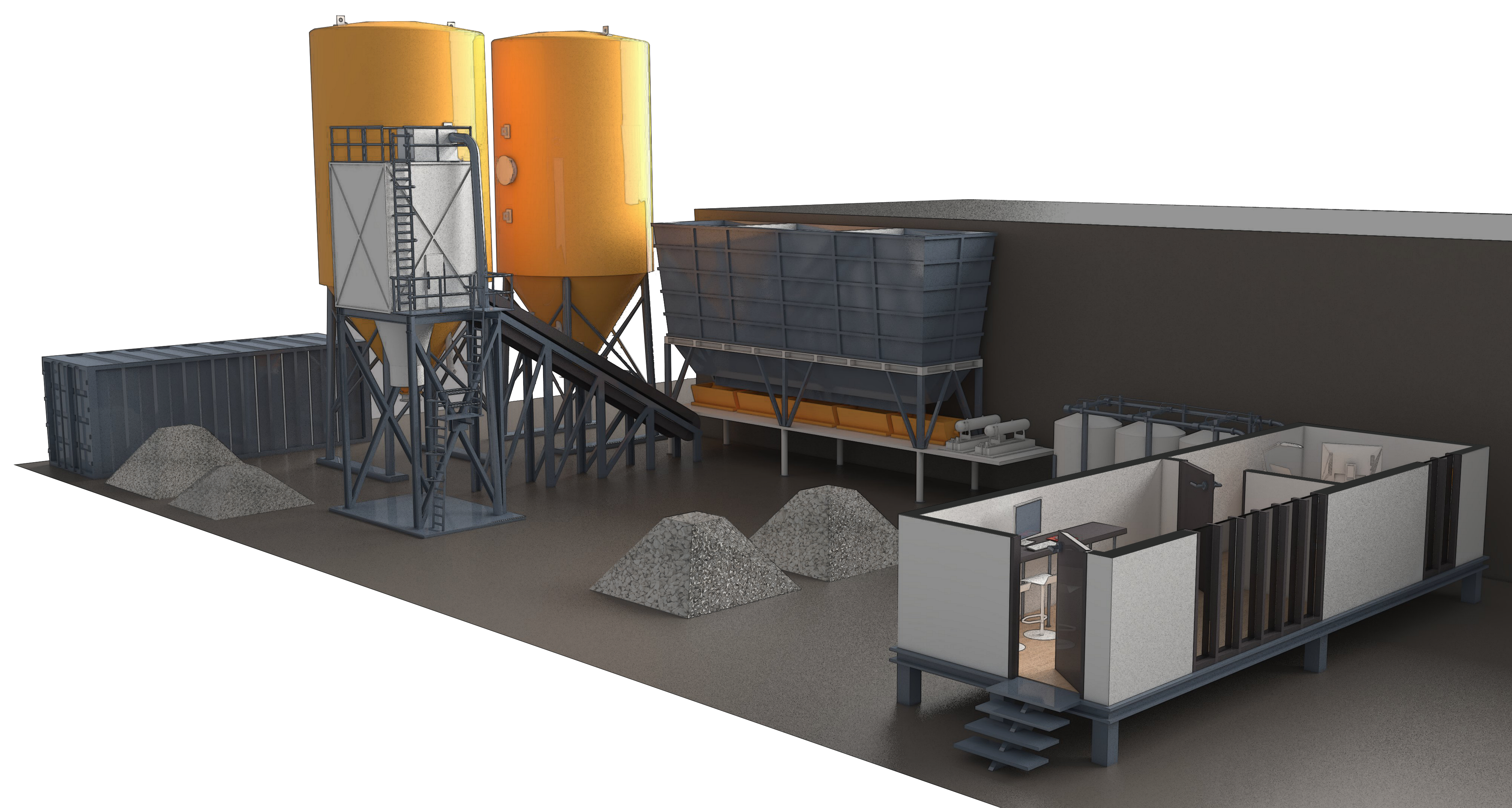

Production details:

- Amount of materials used (readings of load cells or monitoring of hopper capacity)

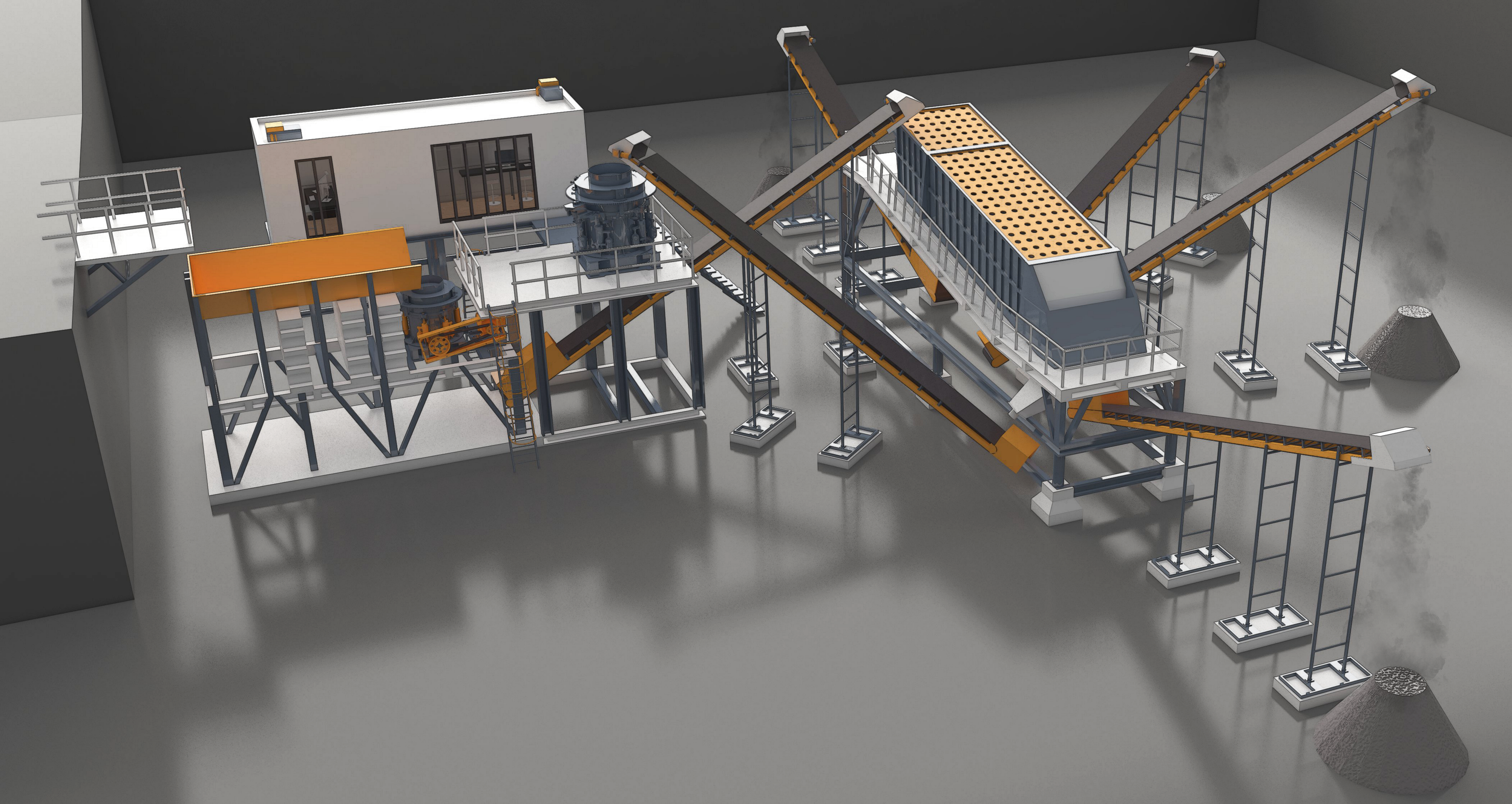

- Differentiating of aggregates while washing: sorting out by grain size

- Production process and energy consumed

- Instant quantities on load cells

- Operational status of the factory: power-on hours and processing

- Amount of output and raw materials consumed.

Alerts

Generation and transmitting of customised alerts via push notifications displayed at your PC, tablet, smartphone and app.

- Production alerts

- Machine enabling/disabling alerts

- Disabling alert and process alerts (e.g., boiler, bitumen heating)

Alerts are activated when a certain parameter (minimum, maximum, average, summary) is either above or below the established threshold.

Costs and emissions

Breakdown of incurred costs of supply of the production plant:

- Electricity costs

- Gas costs

- Bitumen and filler costs

- Unit costs by aggregate

Average CO2 emissions per kWh produced and their weighted impact in the overall environmental impact of the factory

Indices and consumption

Monitoring and control of electric power consumption:

- Overall electricity consumption

- Electricity consumption of a single process (e.g., power plant)

- LPG boiler consumption

- Average productivity [t/h]

- KPI against reference benchmark [kWh/t]