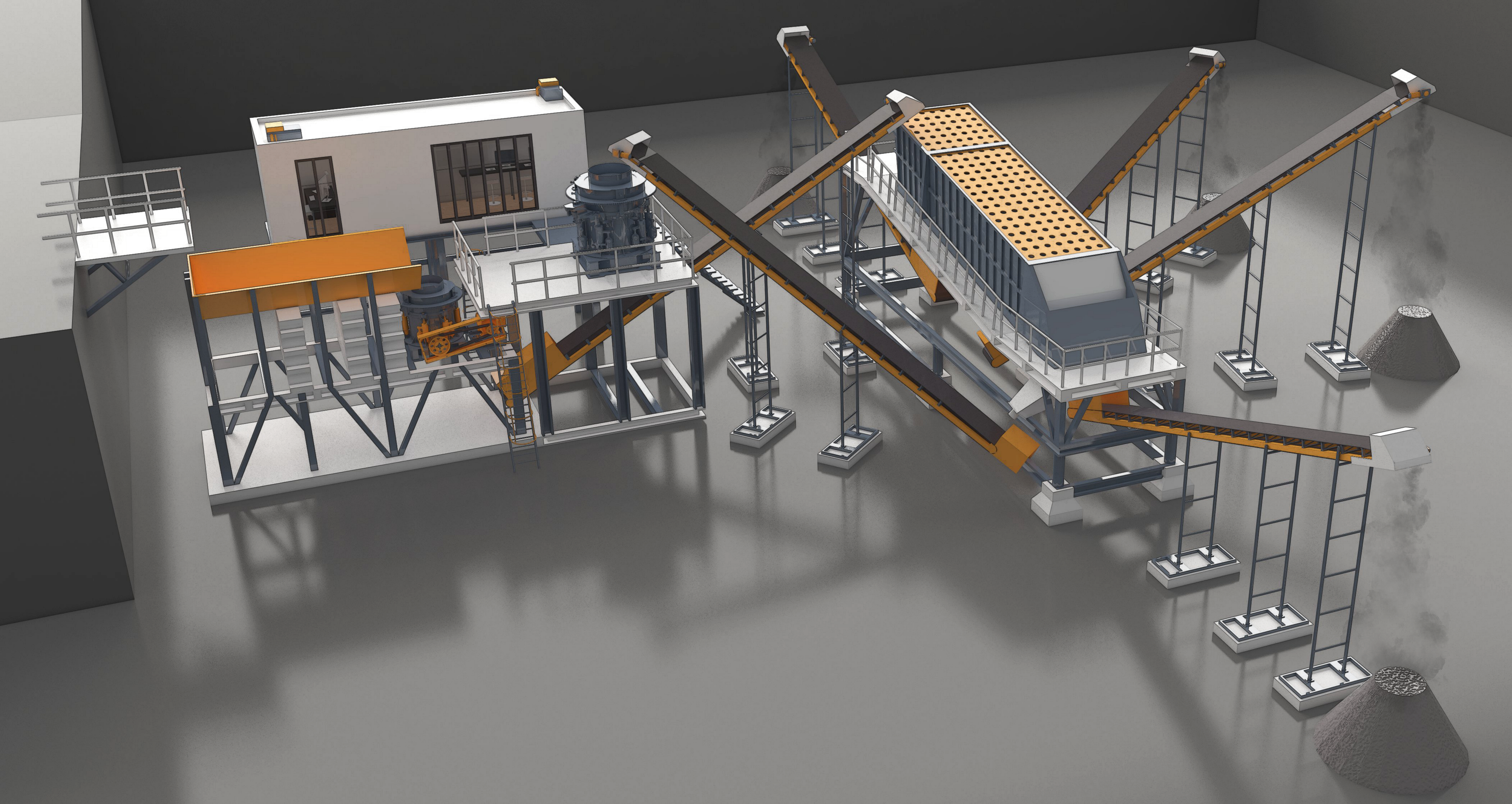

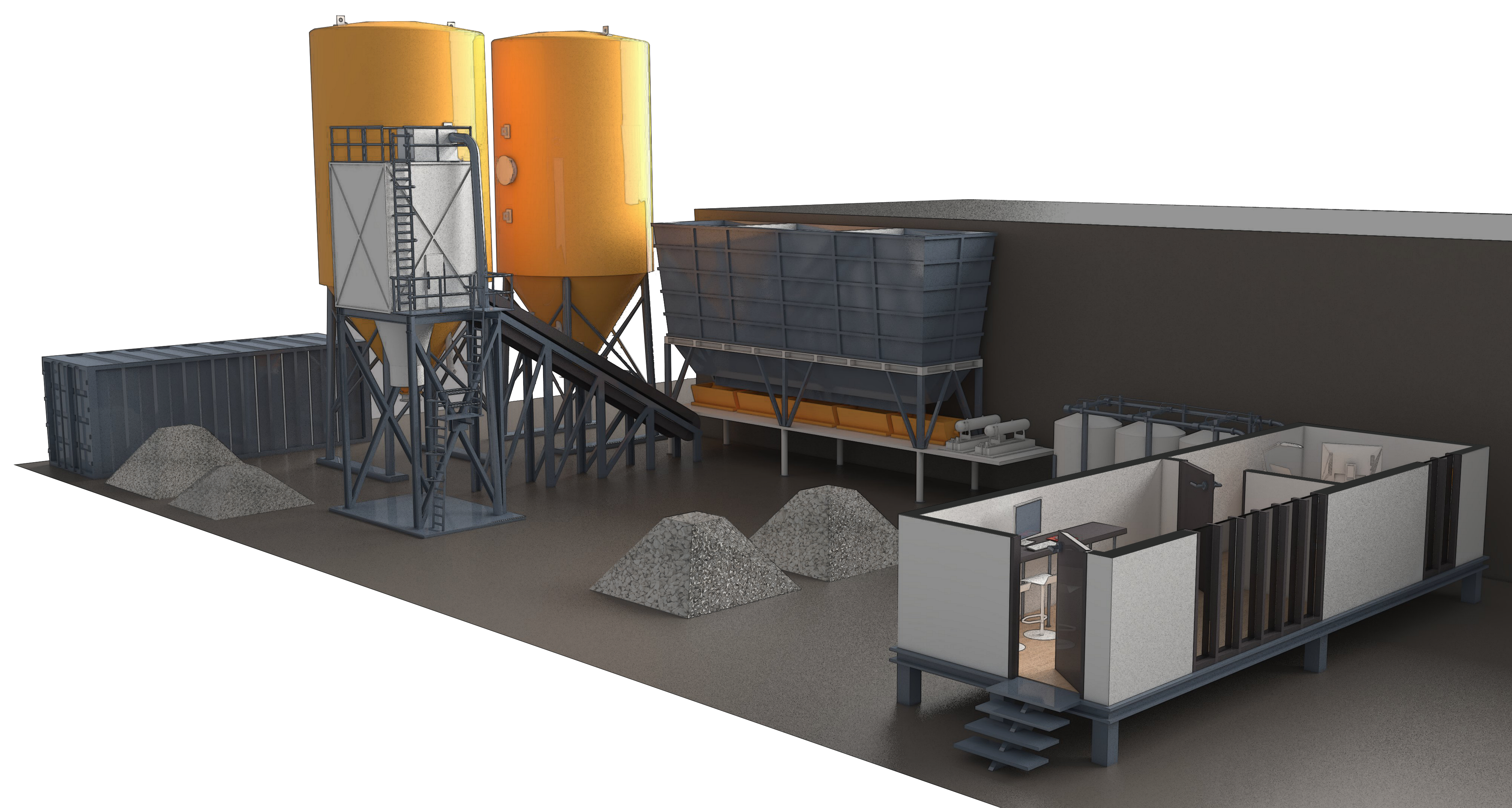

Concrete industry

KontrolON provides companies specialising in producing concrete with a production monitoring system 4.0 with a view to manufacturing high-quality products that are safe both for people and the environment. KontrolON is an efficient tool that enables you to remotely control and streamline your effective production, costs and energy consumption along with the condition of your machinery in real time.

Production data

Production details:

- Aggregates consumption and dosing, sorting out by size in various hoppers (pozzolan material, milled material, sand, crushed stone, gravel)

- Consumption and dosing of cement

- Consumption and dosing of water: amount measured in cubic metres

- Consumption and dosing of solvents

Alerts

Generation and transmitting of customised alerts via push notifications appearing onyour PC, tablet, smartphone and app.

- Factory alerts: activation, deactivation, malfunctioning

Alerts are activated when a certain parameter (minimum, maximum, average, summary) is either above or below the established threshold.

Costs and emissions

Breakdown of the incurred production costs and plant power supply:

- Single material costs: costs of each 100 kg

- Energy carrier costs

- Average CO2 emissions per kWh produced and their weighted impact in the overall environmental impact of the factory

Indices and consumption

Overall factory consumption monitoring:

- Overall consumption: KPI kWh/ or kWh/N° per mixture

- Consumption breakdown by the most energy-intensive carriers (main and secondary production activities)

- Quantity of mixtures produced

- Power-on and operation hours of the plant