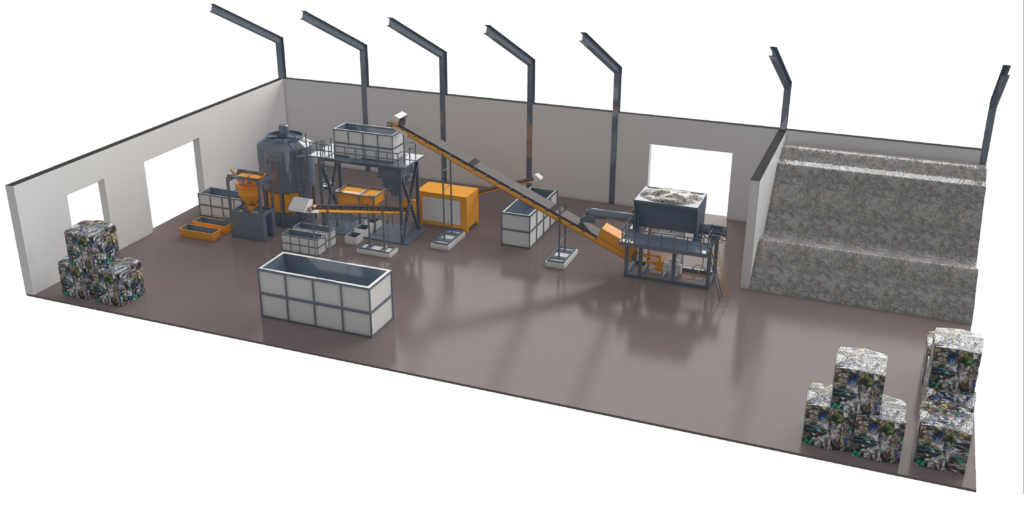

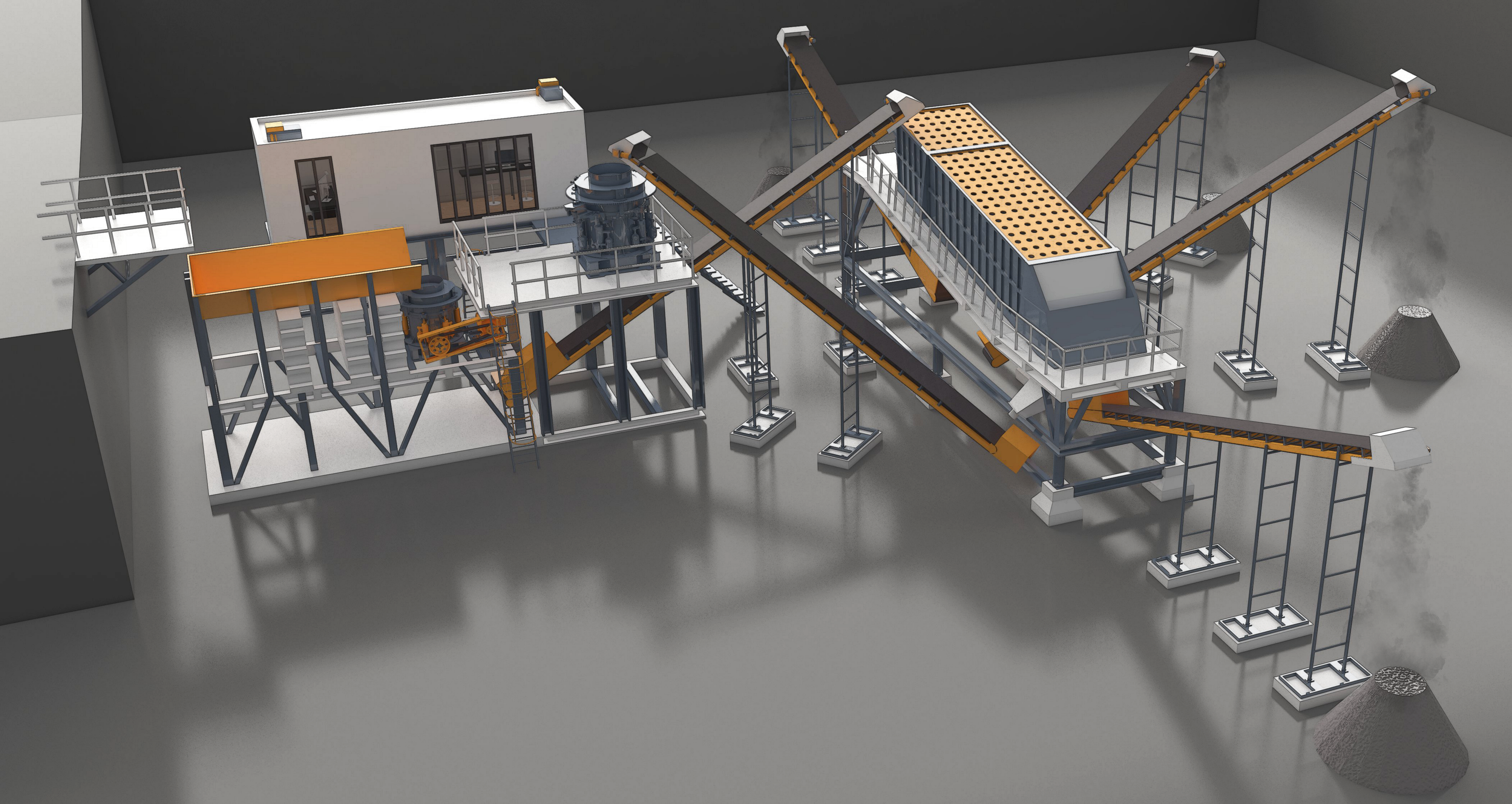

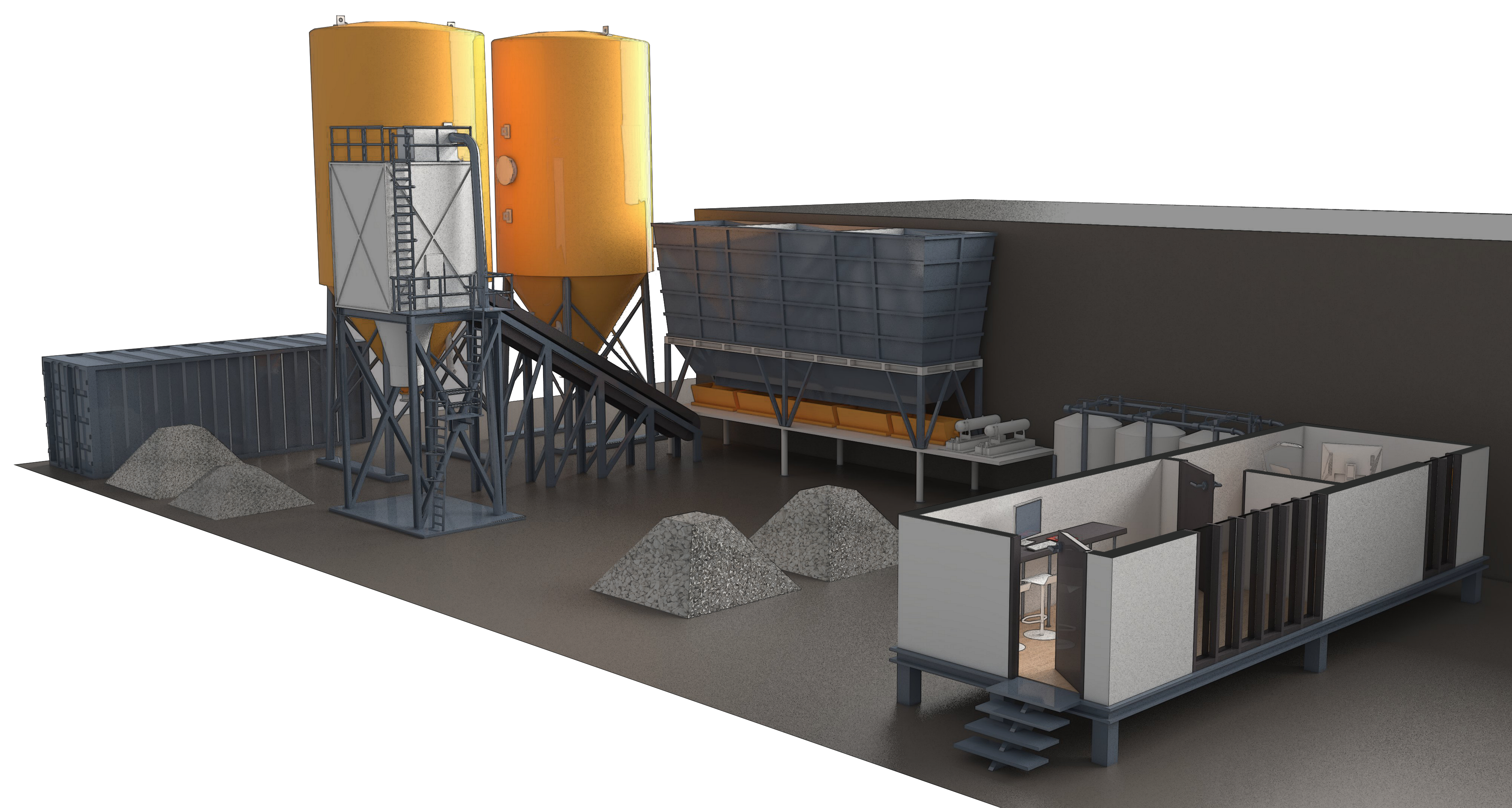

Waste treatment industry

KontrolON enables waste treatment companies to rely on the efficiency of a system designed to monitor and control consumption rates, costs and resources with a view to achieving sustainable and successful production. Thanks to the data provided by KontrolON and to periodic reports, factory owners and personnel involved are able to analyse and work out operational strategies to improve the performance of the company and solve potential problems related to environmental protection.

Production data

Production details:

- Factory operation details: hours worked and power-on hours

- Monitoring of Archimedes’ screws and overhead cranes for loading and moving of digested mass (number of movements of overhead cranes)

- Mixing details (mechanical turning) and aeriation

Alerts

Generation and transmitting of customised alerts via push notifications appearing on your PC, tablet, smartphone and app.

- Factory alerts: activation/deactivation, malfunctioning

- Aeriation alert: activation/deactivation

Alerts are activated when a certain parameter (minimum, maximum, average, summary) is either above or below the established threshold.

Costs and emissions

Breakdown of the incurred costs related to power supply of the factory:

- Overall costs of energy carriers

- Costs of the energy impact of each waste treatment cycle: KPI [kWh/cycle] and KPI [cycle/hour]

- Costs per kWh/m3

- Average CO2 emissions per kWh produced and their weighted impact in the overall environmental impact of the factory

Indices and consumption

Monitoring of overall factory consumption:

- Process consumption (e.g., overhead crane, aeriation) and secondary processes (e.g. purification)

- Overall electric power consumption

- Hours of production, of moving, quantity of production cycles, amount of waste treated

- Consumption of the machinery involved in the process (e.g., press, packing machine, compactor, purifier, etc.)

- KPIs and internal and sector benchmarks